PDGS

PDGS

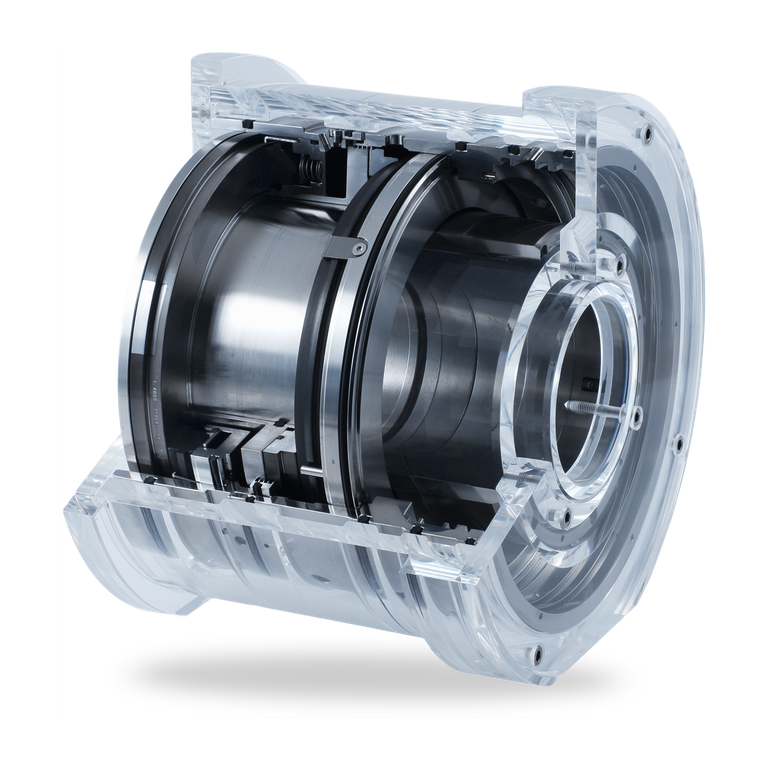

PDGS Tandem seal with intermediate labyrinth

Product links separation seals:

EagleBurgmann CSE

EagleBurgmann CSR

EagleBurgmann CobaSeal

| A | Primary seal gas supply |

| B | Primary vent |

| C | Secondary gas seal supply |

| S | Secondary vent |

| D | Separation gas supply |

| Item | Description |

| 1 | Seal face, stationary |

| 2 | Seat, rotating |

| 3 | Thrust ring |

| 4 | Spring |

| 5 | Shaft sleeve and seat retainer |

| 6 | Intermediate sleeve |

| 7, 8 | Housing (size matched to installation space) |

| 9 | Separation seal (CSR) |

| 10 | Labyrinth |

| 11 | Intermediate labyrinth |

Product links separation seals:

EagleBurgmann CSE

EagleBurgmann CSR

EagleBurgmann CobaSeal

PDGS

Features

- Gas-lubricated

- Uni-directional or bi-directional

- Elastomer-free

- Ready-to-fit cartridge unit

- Single, double, tandem seal and tandem with intermediate labyrinth available

- Separation seals as labyrinths, carbon rings or CobaSeal are optionally available

Advantages

- Wear-free and contact-free operation

- Self-cleaning 3D gas grooves

- High gas film stiffness

- Secure cupped retainer for seat

- Available in various materials for optimized chemical resistance

- Proven, reliable and economical solution

Materials

Seal face: Silicon carbide with DLC coating

Seat: Silicon carbide with DLC coating

Secondary seals: Polymer rings

Metal parts: 1.4006, 1.4313-QT650, Inconel® or other stainless steels.

Other materials on request.

Available also with EagleBurgmann DiamondFace technology.

Seat: Silicon carbide with DLC coating

Secondary seals: Polymer rings

Metal parts: 1.4006, 1.4313-QT650, Inconel® or other stainless steels.

Other materials on request.

Available also with EagleBurgmann DiamondFace technology.

Standards and approvals

- NACE

- API 617

- API 692

Recommended applications

- Oil and gas industry

- Refining technology

- Petrochemical industry

- LNG

- CCUS

- Hydrogen

- Power generation

- Hydrocarbon gas

- Ammonia

- Nitrogen

- Refrigerants

- Air

- Centrifugal compressors

- Turbo expanders

- Blowers

Notes

A well-established compressor seal for high pressure and both low and high temperature applications. Innovative

design features allow it to cope with even the highest pressures without problems. The application of U-cups and special dynamic sealing elements opens up a wide range of uses for this versatile and successful seal series.

Dimensions on request.

Dimensions on request.

Product variants

PDGS10

The PDGS10 is the standard seal for high pressures up to 220 bar (3,191 PSI). Since many years the seal demonstrates their reliability worldwide in a wide variety of applications. It is characterized by very low leakage and sets the standard in the market for low-emission compressor gas seals.

Operating range

Shaft diameter:

d = 24.5 … 360 mm (0.96“… 14.17“)

Pressure (static): p = 0 … 220 bar (725 … 3.191 PSI)

Pressure (dynamic): p = 0 … 200 bar (725 … 2.901 PSI)

Temperature:

t= -50 °C … +230 °C (-58 °F … +446 °F)

Sliding velocity: vg = up to 227 m/s (744 ft/s)

Materials

Seal face: Silicon carbide with DLC coating

Seat: Silicon carbide with DLC coating

Secondary seals: Polymer rings

Metal parts: 1.4006 or other stainless steels

The PDGS10 is the standard seal for high pressures up to 220 bar (3,191 PSI). Since many years the seal demonstrates their reliability worldwide in a wide variety of applications. It is characterized by very low leakage and sets the standard in the market for low-emission compressor gas seals.

Operating range

Shaft diameter:

d = 24.5 … 360 mm (0.96“… 14.17“)

Pressure (static): p = 0 … 220 bar (725 … 3.191 PSI)

Pressure (dynamic): p = 0 … 200 bar (725 … 2.901 PSI)

Temperature:

t= -50 °C … +230 °C (-58 °F … +446 °F)

Sliding velocity: vg = up to 227 m/s (744 ft/s)

Materials

Seal face: Silicon carbide with DLC coating

Seat: Silicon carbide with DLC coating

Secondary seals: Polymer rings

Metal parts: 1.4006 or other stainless steels

PDGS15

The PDGS15 series enable the sealing of very cold media up to -200 °C (-328°F) . Therefore special, cold-resistant steels are used. For years, these seals are successfully used in LNG liquefaction plants, for example.

Operating range

Shaft diameter:

d = 24.5 … 360 mm (0.96“… 14.17“)

Pressure (static and dynamic): p= 100 bar (1450 PSI)

Temperature:

t = -200 °C … +150 °C (-328 °F … +302 °F)

Sliding velocity: vg = up to 227 m/s (744 ft/s)

Materials

Seal face: Silicon carbide with DLC coating

Seat: Silicon carbide with DLC coating

Secondary seals: Polymer rings

Metal parts: 1.4313-QT650 or other stainless steels

The PDGS15 series enable the sealing of very cold media up to -200 °C (-328°F) . Therefore special, cold-resistant steels are used. For years, these seals are successfully used in LNG liquefaction plants, for example.

Operating range

Shaft diameter:

d = 24.5 … 360 mm (0.96“… 14.17“)

Pressure (static and dynamic): p= 100 bar (1450 PSI)

Temperature:

t = -200 °C … +150 °C (-328 °F … +302 °F)

Sliding velocity: vg = up to 227 m/s (744 ft/s)

Materials

Seal face: Silicon carbide with DLC coating

Seat: Silicon carbide with DLC coating

Secondary seals: Polymer rings

Metal parts: 1.4313-QT650 or other stainless steels

PDGS51

The PDGS51 was developed for use in extreme high pressure applications. Adapted sliding faces and an innovative design of the shaft sleeve allow pressures up to 450 bar (6.525 PSI) and more. Most of these seals are successful in use in compressors for gas injection.

Operating range

Shaft diameter:

d = 85.5 … 173 mm (3.37“… 6.81“)

Pressure (static and dynamic): p = up to 650 bar (7.977 PSI)

Temperature:

t = -50 °C … +230 °C (-58 °F …+446 °F)

Sliding velocity:

vg = 0,6 …. 190 m/s (2 … 623 ft/s)

Materials

Seal face: Silicon carbide with DLC coating

Seat: Silicon carbide with DLC coating

Secondary seals: Polymer rings

Metal parts: 1.4006 or other stainless steels

The PDGS51 was developed for use in extreme high pressure applications. Adapted sliding faces and an innovative design of the shaft sleeve allow pressures up to 450 bar (6.525 PSI) and more. Most of these seals are successful in use in compressors for gas injection.

Operating range

Shaft diameter:

d = 85.5 … 173 mm (3.37“… 6.81“)

Pressure (static and dynamic): p = up to 650 bar (7.977 PSI)

Temperature:

t = -50 °C … +230 °C (-58 °F …+446 °F)

Sliding velocity:

vg = 0,6 …. 190 m/s (2 … 623 ft/s)

Materials

Seal face: Silicon carbide with DLC coating

Seat: Silicon carbide with DLC coating

Secondary seals: Polymer rings

Metal parts: 1.4006 or other stainless steels

Similar products

CobaDGS - Zero Emission Solution

The sealing solution for reduction of methane-/ process gas emissions

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

- Available for following seal arrangements: single and tandem

- Co-axial primary seal

- Separation seals as CobaSeal, carbon rings or labyrinths optional

DGS

- Gas-lubricated

- Uni-directional or bi-directional

- Ready-to-fit cartridge unit

- Single, double, tandem and tandem with intermediate labyrinth available

- Separation seals as labyrinths, carbon rings or CobaSeal are optionally available

MDGS

- Gas-lubricated

- Bi-directional

- Compact, radial design

- Ready-to-fit cartridge unit, also available as a component seal

- Single, double, tandem seal and tandem with intermediate labyrinth available